Choosing the right Stainless Hex Nuts is crucial for any successful project. According to industry expert John Harris, “Quality nuts support structure integrity.” This insight highlights the importance of selecting suitable materials and sizes.

Stainless Hex Nuts come in various grades and dimensions. Each type serves different applications and environments. For example, a marine project requires rust-resistant nuts. In fast-paced construction, durability is essential. Understanding these needs helps prevent costly mistakes.

Many overlook the specifics of these components. A wrong choice can lead to project delays or even failures. The right Stainless Hex Nuts should match your project’s requirements closely. Reflecting on your choices ensures that they align with your functional and aesthetic needs.

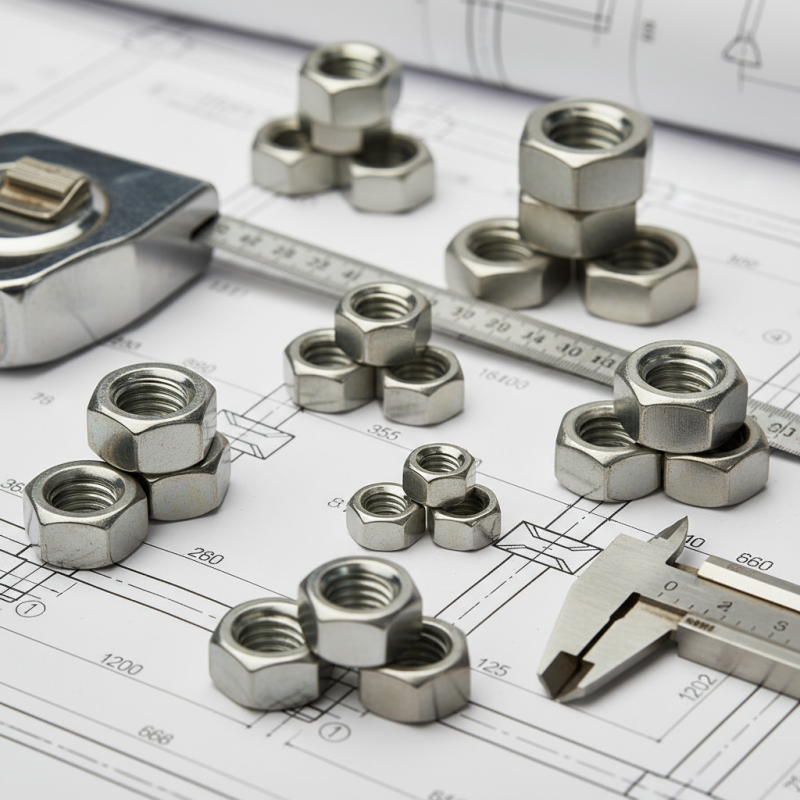

When selecting stainless steel hex nuts, understanding the different types available is crucial. Hex nuts generally fall into several categories. There are standard hex nuts, lock nuts, and flange nuts. Each type serves a specific purpose in various applications. For example, standard hex nuts are versatile and suitable for general use. Lock nuts provide extra security against loosening. Flange nuts have a built-in washer and offer better load distribution.

Consider the material grade when choosing stainless hex nuts. Common grades include 304 and 316. Grade 304 is sufficient for many indoor projects. However, grade 316 is more resistant to corrosion, making it ideal for marine environments. Keep in mind that not all projects require the highest grade. It’s easy to overspend if you're not careful.

Size is another vital factor. You need to match the nut size to your bolts accurately. Too loose, and it won't hold; too tight, and you risk damage. Measure carefully and consider the thread pitch. Inconsistent threads can lead to frustration during assembly. Think about your project's specific needs. In the end, the right choice can save time and enhance durability.

When evaluating the strength and durability requirements for your project, the type of stainless hex nuts is crucial. Different grades of stainless steel offer varying levels of corrosion resistance and structural integrity. For example, A2 stainless steel provides moderate corrosion resistance, while A4 steel is more suited for marine environments. According to industry data, grade A4 has a tensile strength reaching 800 MPa, making it ideal for high-stress applications.

Durability should not be overlooked. Environmental conditions can significantly affect performance. A study highlighted that stainless fasteners can lose up to 40% of their strength when subjected to extreme temperatures. Proper selection involves understanding these factors. It's essential to assess not just the tensile strength, but also the intended environment. Will the nuts face saltwater, chemicals, or extreme heat? Each factor will shape your choice.

Another overlooked aspect is the potential for galvanic corrosion. Using dissimilar metals can lead to issues. This phenomenon occurs when two different metals are in contact and lead to accelerated corrosion. Therefore, compatible materials must be chosen. Regular inspections are also necessary to ensure ongoing durability. Balancing these considerations can be challenging, but it is vital for long-lasting results.

Choosing the right stainless hex nuts for your projects requires careful attention to size and thread specifications. The right size ensures a secure fit and optimal load-bearing capacity. According to industry reports, nearly 70% of mechanical failures are due to improper fastener selection. Therefore, measuring the diameter and length of the bolts you intend to use is crucial.

Thread specifications matter just as much. Common options include UNF (Unified National Fine) and UNC (Unified National Coarse) threads. A mismatch can lead to poor engagement and might even strip the threads over time. Research indicates that proper engagement improves overall joint integrity by 30%. It's essential to consider the environment as well. For instance, marine applications require coatings to prevent corrosion, while other settings might not.

When selecting nuts, think about the material's strength and the environment. Tensioning requirements differ based on the application, leading to potential oversight in choosing the appropriate grade. Many professionals overlook this, leading to project delays. Using strength data from the ASTM standards can help guide your decisions. Ultimately, recognizing the nuances of sizing and threading could prevent costly mistakes down the line.

Choosing the right stainless hex nuts involves careful consideration of environmental factors, especially corrosion resistance. Corrosion can lead to significant structural failures. A report from the Corrosion Engineering Association states that corrosion costs the U.S. economy about $276 billion per year. Understanding the environment where your fasteners will be used is crucial.

For instance, if your project is in a coastal area, select nuts with higher corrosion resistance. Marine environments can be particularly harsh. This is due to the presence of salt in the air, which accelerates corrosion. Grade 316 stainless steel is often recommended for such conditions. It contains molybdenum, enhancing its resistance to pitting and crevice corrosion.

Additionally, consider the combined effects of temperature and moisture. High humidity can exacerbate corrosion even in stainless steel. A study by the National Association of Corrosion Engineers indicated that humidity levels above 50% significantly increase the risk of corrosion. Sometimes, achieving the right balance between cost and durability is challenging. Skimping on quality may save money initially but could lead to costly replacements later on.

| Type of Stainless Steel | Corrosion Resistance Rating | Common Applications | Temperature Range (°C) |

|---|---|---|---|

| 304 Stainless Steel | Good | General applications, Food processing | -196 to 800 |

| 316 Stainless Steel | Excellent | Marine applications, Chemical processing | -196 to 870 |

| 410 Stainless Steel | Fair | Mildly corrosive environments, Automotive | -30 to 650 |

| Duplex Stainless Steel | Very Good | Oil and gas, Pulp and paper | -50 to 300 |

When choosing stainless hex nuts, compatibility with other fasteners is crucial. According to industry reports, mismatched components can lower the strength of your assembly. For instance, using a low-grade bolt with a high-grade nut can lead to premature failure. Ensure that the grade markings on your nuts and bolts align. Stainless steel grades such as 304 and 316 are common, but they serve different purposes.

Consider the diameter and thread pitch of the hex nuts. Mismatched sizes can cause loose fittings or stripped threads. Always compare the specifications of your fasteners. It’s critical to check measurements thoroughly. Use calipers to ensure accuracy, as even slight discrepancies can result in issues.

Tips:

For more information, fill out our contact form